mike

Junior Member

Posts: 67

|

Post by mike on Jul 3, 2016 8:51:54 GMT -9

Packing the gears keeps them aligned with the reaction shaft. If they moved trying get the Tc fully seated would be frustrating.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 3, 2016 8:52:50 GMT -9

I'm a double posting fool this morning !!  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 3, 2016 9:01:49 GMT -9

Precision industries billet input  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 6, 2016 18:28:14 GMT -9

Here's the case all cleaned up. Nothing a little brakleen and a pressure washer can't handle  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 6, 2016 18:30:25 GMT -9

I added this little hole .750" from the center bore. On the other side of the case it adds extra oil to the sprag/roller clutch.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 6, 2016 18:31:47 GMT -9

Here's the view from inside the case  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 6, 2016 18:36:32 GMT -9

It's kind of hard to see but I ditched the factory wave snap rings that cushions the 2-3 shift a little and possibly promotes slippage and added heat. I replaced it with a .062" snap ring and had my buddy with a lathe shave my factory pressure late down so I could fit an extra friction and steel. Clearance comes out at .070" and that's a bit tighter than the factory spec but a lot of builders like to tighten that drum up. It's still .014" of clearance per friction so I should be just fine.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 12, 2016 1:17:17 GMT -9

So my Trans was shifting consistently at 2900/3000 at wot. The truck accelerates much faster if I hold the shifts at 3500 rpms manually but that is not a very consistent way to drive this truck as the column is old . I've been tempted to go with a full manual valve body, and a custom slap shifter/ center console setup but my wife drives this truck a few times a month and I don't want her having to deal with a manual vb.

Once I get to the valvebody portion of this rebuild I'll cover some things there for raising shift points. Since 1-2 and 2-3 shift are already at the same rpm and I have the hydraulic governor apart I'm going to be playing with the centrifugal weight/valve that's responsible for raising line pressure and causing the valve body up shift to the next gear once it sees x amount of pressure. I have some spare gov parts off an older 727 torqueflite and a spare diesel 47rh governor. By lightening the weight / valve assembly it's going to cause later 1-2 and 2-3 shift points.

The diesel version of these trans typically see 3 psi per mph up until 3rd gear and the pressure peaks. Some gasser Trans see 1 psi per mph. There's no exact amount of weight for me to remove from the weight/valve assembly To achieve the exact rpm per gear shift increase. The governor is located in the very back of the overdrive housing and is a pia to get to when the Trans is in the truck. So I started weighing different gov weights. I'm I kin some up tomorrow from a tranny shop . The diesel weights are brass and the heaviest, v8 gasser is the lightest - aluminum, and 47rh gov weights that are from a v10 truck would be ideal.

But I think I'll err on the slightly to heavy side and keep the shifts from being up near 4k rpm or more. If I need some more rpm after the gov mods I'll try a stiffer spring on my throttle valve on the valve body. The stiffer the spring the later the up shift- but you can only go far with the TV settings.

|

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 12, 2016 1:18:17 GMT -9

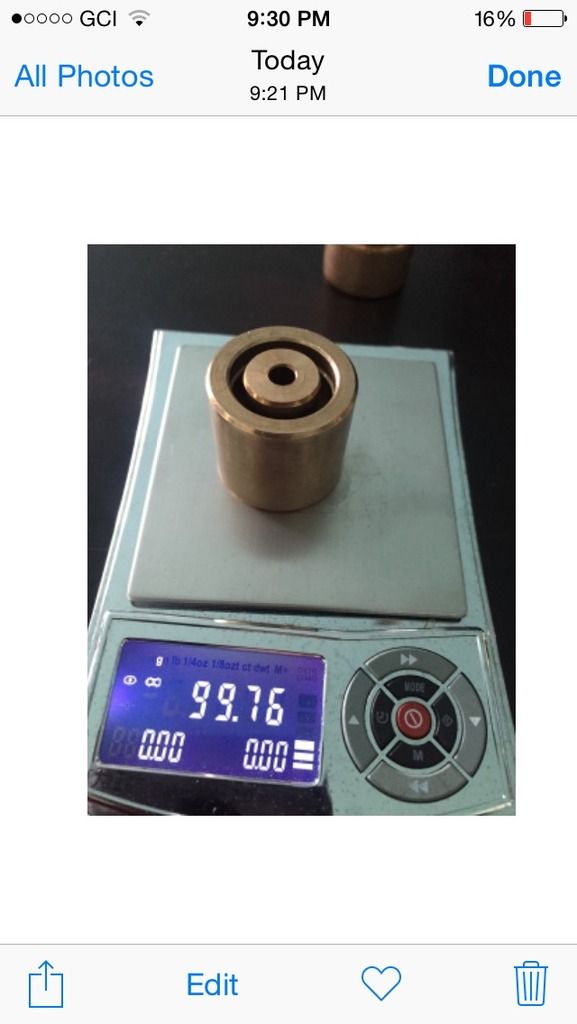

Here is the heaviest combo I had - 2900/3000 rpms |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 12, 2016 1:22:00 GMT -9

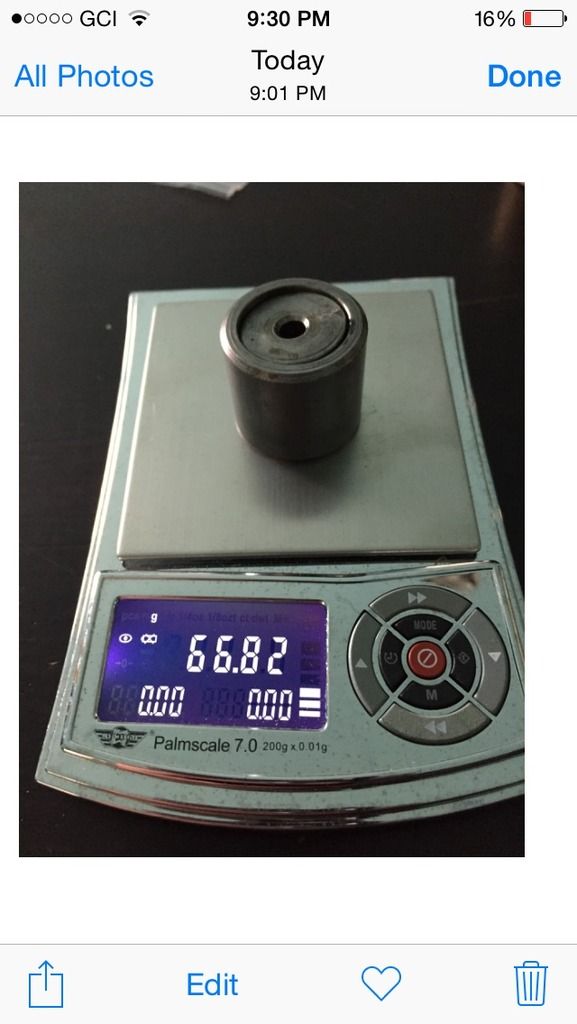

Here is the steel gov weight from the early 70s Chrysler Newport 727 trans. It had a 400 big block and I assume the shift points were not very high for a v8 car but they were probably to high for my application.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 12, 2016 1:25:42 GMT -9

Here is the slightly lighter than stock combo I have . 11 grams lighter. If I cannot find another rh gov setup tomorrow I may havey machinist buddy help me shave some weight off. Maybe another 6-10 grams. This is the steel inner weight with the brass outer weight  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 12, 2016 1:26:38 GMT -9

Here is the inner weights . They ride on a spring inside of the larger weight and use a snap ring to keep them assembled.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 12, 2016 1:28:03 GMT -9

Damn double post  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 9:55:30 GMT -9

My friend has a nice setup at his shop - AC machine works LLC.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:01:15 GMT -9

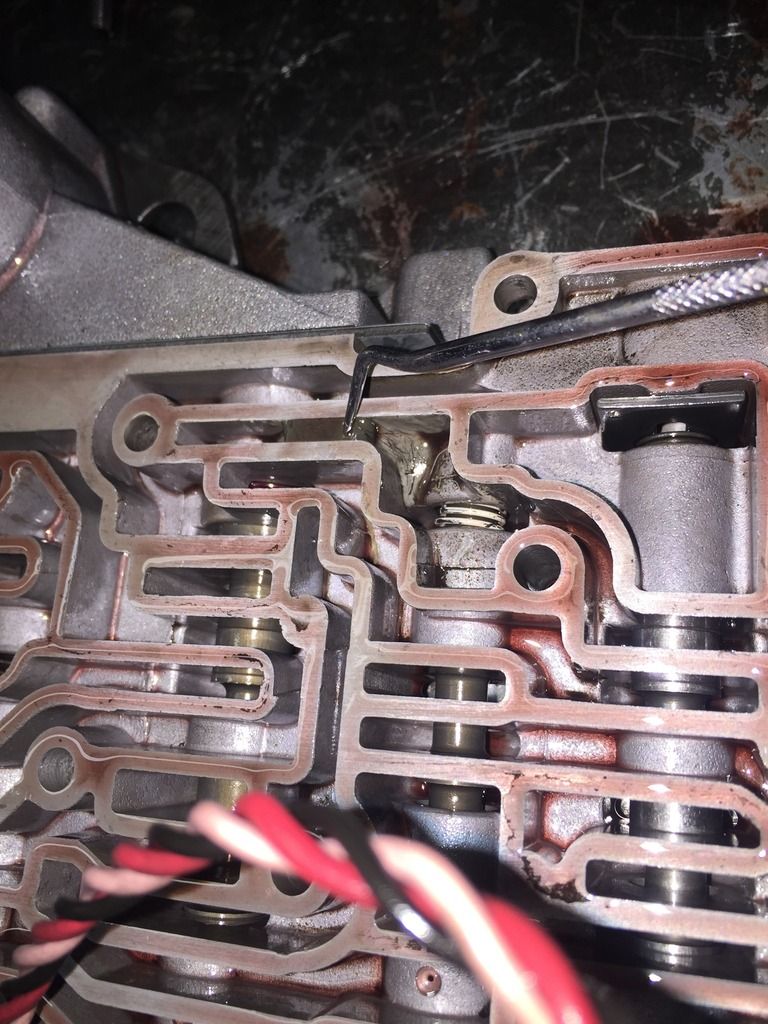

Onto the valve body. Now I have a lock up switch but if you have a stock valve body (vb) then Tc lock up only works if you leave the truck in D. Manual shifting does not work with a Tc lu switch unless you modify the vb at this passage. I used jb quick weld. This is a common mod that allows you to run manual 2nd gear with a Tc LU switch. It makes for cooler tranny temps when beach cruising - i do a lot of beach cruising.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:07:56 GMT -9

Here is a plate mod that isn't covered in the Transgo kit. I upgraded my work tcc timing valve and these mods came with the valve instructions. Trim the plate and enlarge he hole. This adds lockup pressure  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:12:54 GMT -9

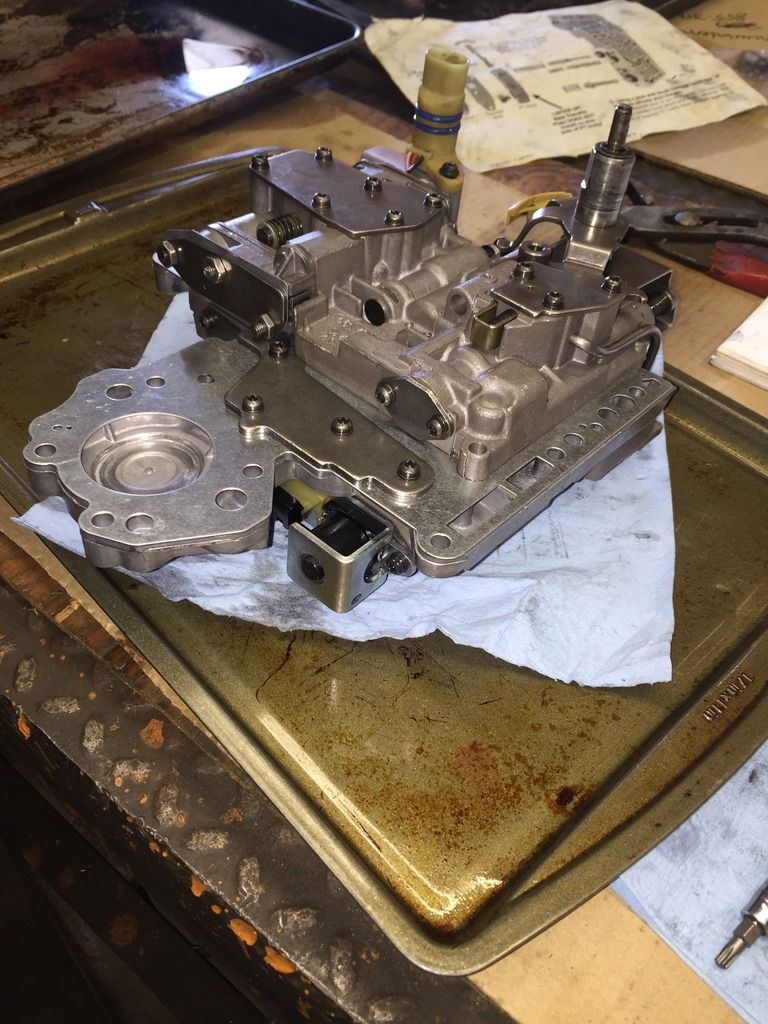

Cookie sheets are a must have for valve body work. They work great for carb rebuilds also  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:15:33 GMT -9

Almost done with the vb. brakleen and compressed air make these things shine.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:22:43 GMT -9

Here is a pic of the upgraded pressure regulator springs and switch valve. I have the line pressure screw turned in 3-4 extra rotations from the hp settings for the kit. Mine was at 175 psi for 30k miles. I added a couple extra turns. Should be around 180 maybe a little more. Come to find out I had the stock TV spring in. I threw an extra green I had into the vb - that should increase wot up shift Rpm's. I also added the spring labeled- 24v/gas applications. I assume that's for higher Rpm up shifts as well. I though I already had these installed from the previous build- that spring goes into the "pt" valve. I should have a taken more pics but I get into assembly mode and forget sometimes.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:26:32 GMT -9

Here is a little trick I should have included in the beginning- the bolts that hold the overdrive to the main case thread into 2 special holes on the pump. You use a slide hammer to pop the pump out. You can also pry on the between the low/reverse drum and the sun shell. I prefer the slide hammer with vise grips welded on.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:32:06 GMT -9

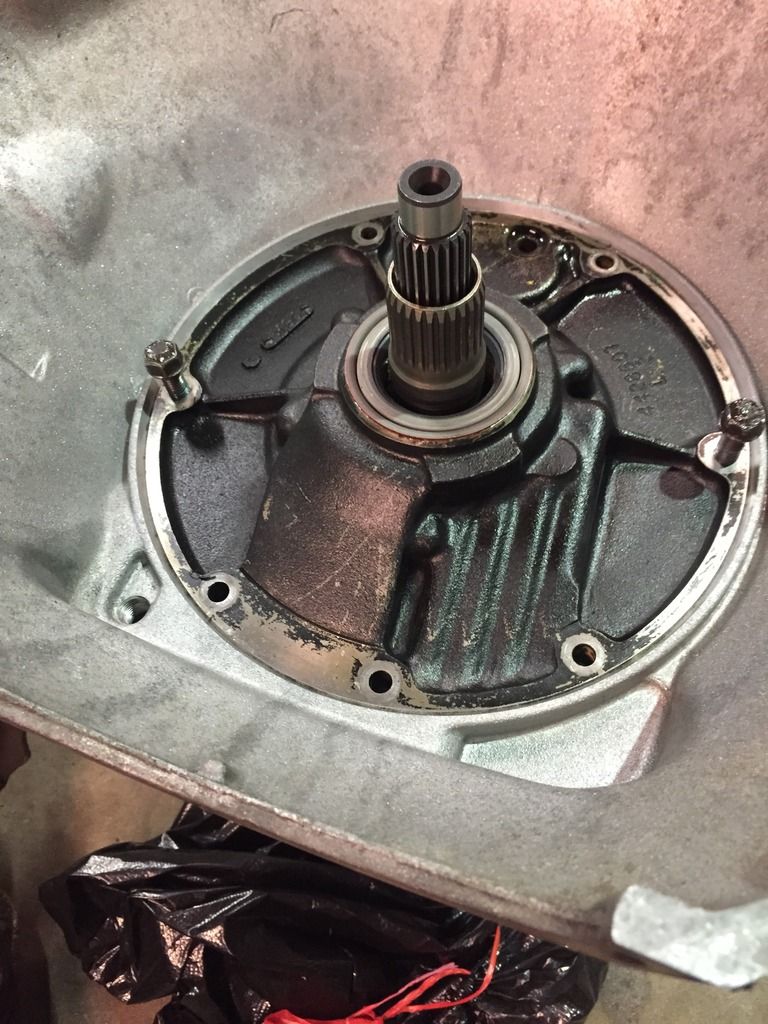

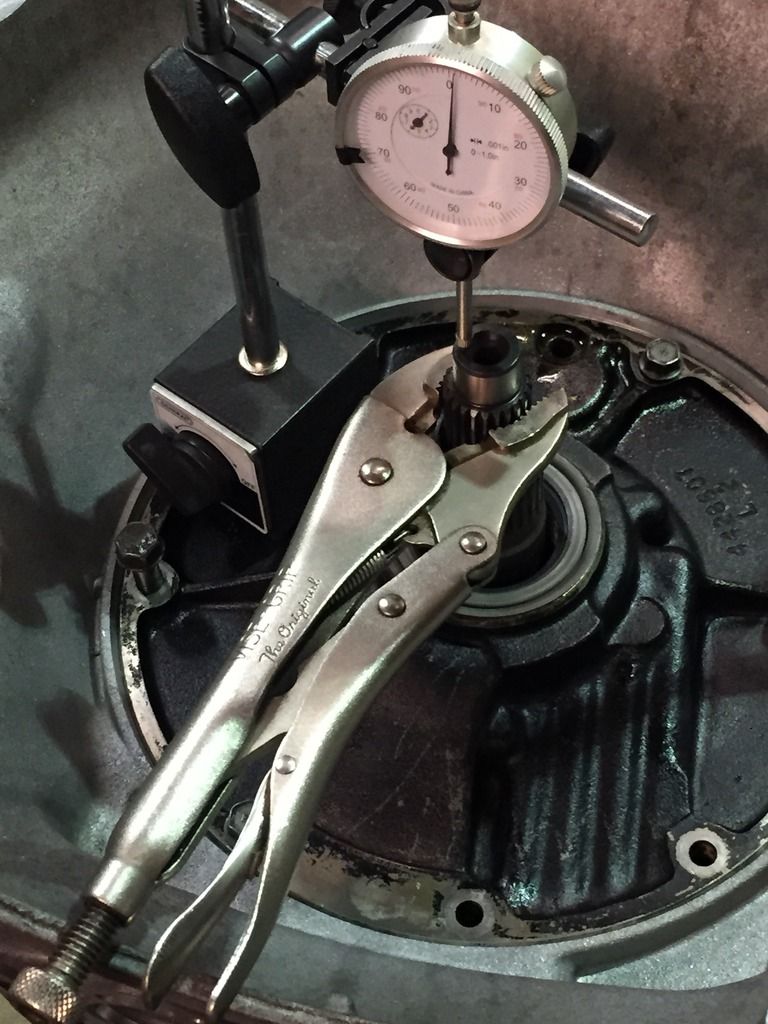

Here I am checking the overall endplay. The book spec is .022"-.090". That is a very wide range. A lot of sled pullers, drag racers and tranission builders prefer to run a tighter clearance. Goerend prefers .035-.045 , some others prefer .055-.075 Mine is set at .044 Here is a pic of the setup. Overdrive must be attached for the this to work  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:37:29 GMT -9

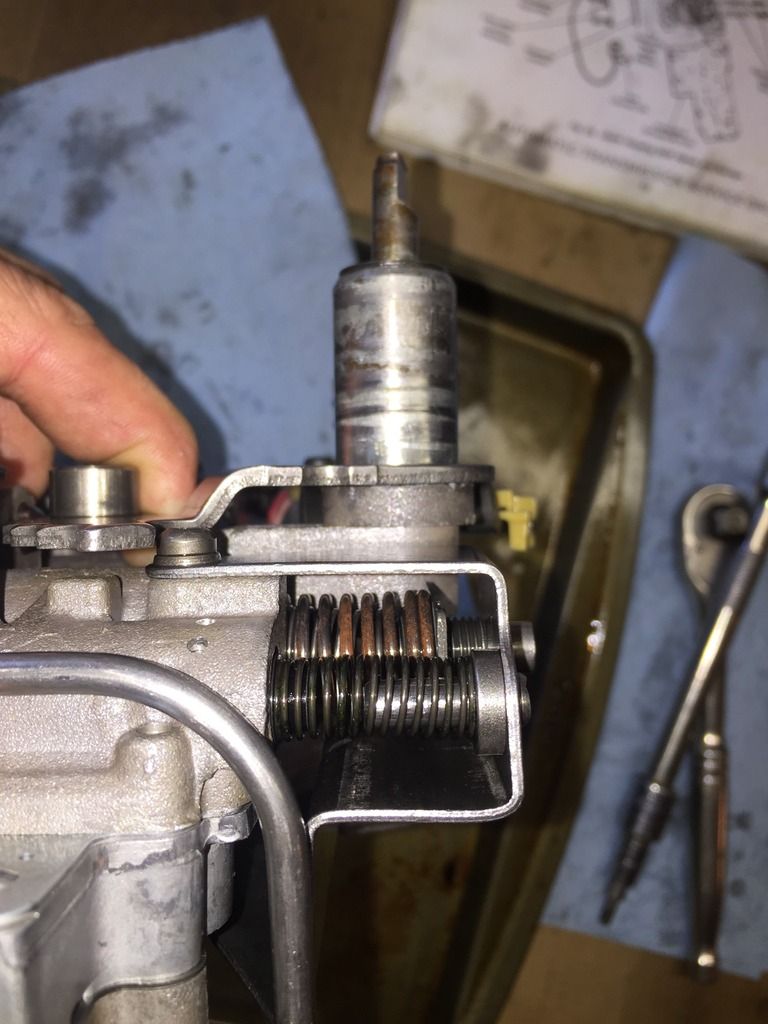

Here is the sonnax super servo being installed. It works well with the 4.2 apply lever, hd strut and anchor. I'm running 2 internal springs instead of one. That helps prevent bind up on the 2-3 shift. "Shift overlap". It's a mother to get it in the case. One trick I do is pack the snap ring retainer groove with assembly grease. I've had the cast ring hang up in the groove and cause me a lot of grief. Then I use these big cowboy clamps and snap it it with one quick movement.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:41:55 GMT -9

There are 2 ways of setting the front band- snug it up to 72" lbs and back it off 2.5 turns or so Or adjust it for 3/8" clearance.- that's what I do. I go by the book for the rear band - 3.5 turns out. The front band adjustment can be altered if I'm experiencing shift overlap.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Jul 16, 2016 10:51:29 GMT -9

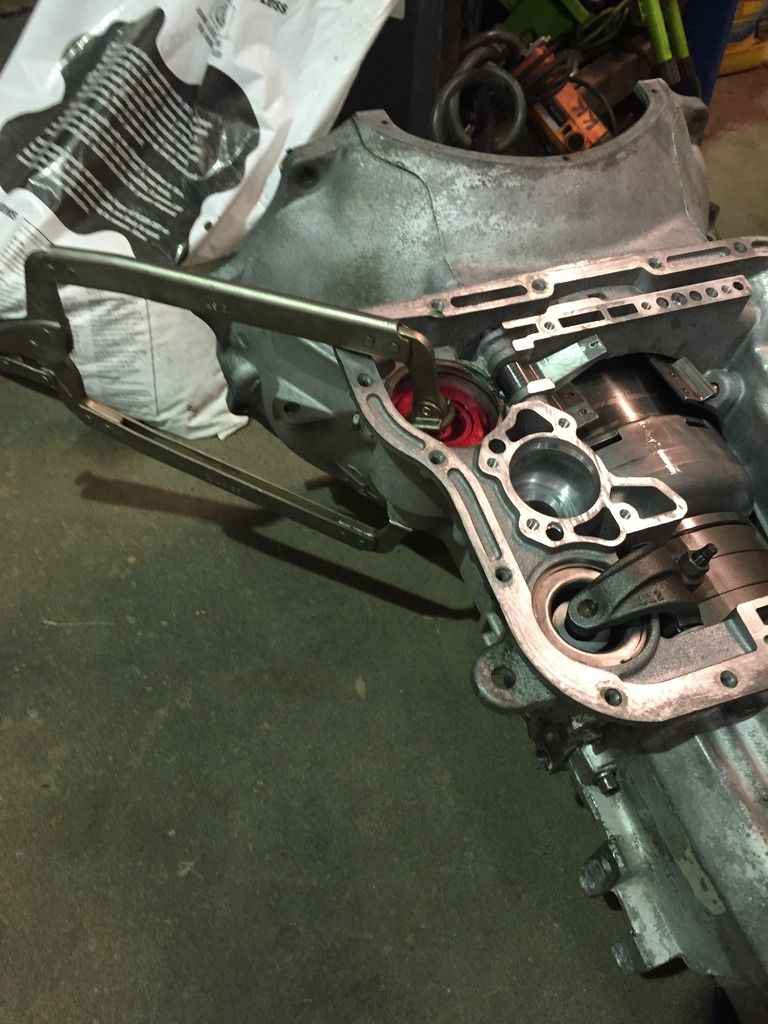

I forgot to take pics during the overdrive rebuild. It has a tcs billet output shaft, the rest of the rebuild is by the book except for the over drive brake clutches. They supply friction that transmits power through the overdrive planetary gears. Mine were toast so I upped the count this time around. I purchased a 48re stepped backing plate to replace my stock piece. It's thinner and allows me to use an extra friction and steel. I increased the count from 5 clutches and steels to 6 clutches and steels. Here is a pic of the finished Trans. Next will be the turbo install.  |

|

mike

Junior Member

Posts: 67

|

Post by mike on Aug 20, 2016 15:49:05 GMT -9

Update- the double springs behind the front servo were a mistake along with that I flipped the orientation between the overdrive selective washer and bearing. Don't ever do that. 20 miles later and I had to pull the tranny again.

So I'm just about done rebuilding it again. I liked the stall speed of the tc and the governor weight mods paid off. This Trans is shifting at 3200 wot. I'm going to try shimming the already stiffer green TV spring it has so I can move wot shift points up higher.

This 64mm with the 5x.016s and 2100 stall are a nice combo and 55 psi is pretty fun. It also dropped my egts by at least 500*

|

|

mike

Junior Member

Posts: 67

|

Post by mike on Sept 26, 2016 18:12:28 GMT -9

Truck is alive !!!!! This turbo added 6-700 rpm of power band. It winds out to 3500 now , where it use to nose over at 2700.

|

|

|

|

Post by Administrator on Oct 3, 2016 16:56:21 GMT -9

This thread is awesome! Thanks for keeping up on it Mike, very well done. Makes me want to rebuild a transmission. lol.

|

|

mike

Junior Member

Posts: 67

|

Post by mike on Oct 3, 2016 18:49:31 GMT -9

The altered 1-2 governor plug in the Transgo TFOD HD2 shift kit was causing major issues also. It does say in the instructions " not for diesel or rv" this is the best one I've built out of 7 units. Devon was cool gave me a couple tips when I was picking his brain.

I backed the truck off to mid 40s for boost and it doesn't seem much slower. I am on stock head bolts still with 19 timing , 5x.016s and delivery valves along with that 64mm I'm asking for a headgasket to pop. I'm going to try some 130$ "mighty diesel head bolts " the dealer is running 30* timing and 70 psi on his puller. Should be good for my 500 hp truck- combo is good for 600+ but my timing is that high

You should try building a trans. I've only done the 07' and older styles but they are fairly simple

|

|

|

|

Post by Administrator on Oct 4, 2016 22:35:52 GMT -9

I've built a few, years ago, pre-internet. LOL. That just sounds weird.

I find this thread inspiring. I've got an early 90's Chevy half ton in my back yard that I need to do the transmission on so I can use it for a plow truck. The race truck is in the way though so I will just have to wait until the plow truck dies, or I get my act together and finish the race truck.

Thank you for sharing!

|

|

mike

Junior Member

Posts: 67

|

Post by mike on Oct 5, 2016 14:57:56 GMT -9

Thanks! Correction - I have the front band torqued to 72 inch lbs and backed off 1 7/8" turns.

|

|